Tool Fabrication

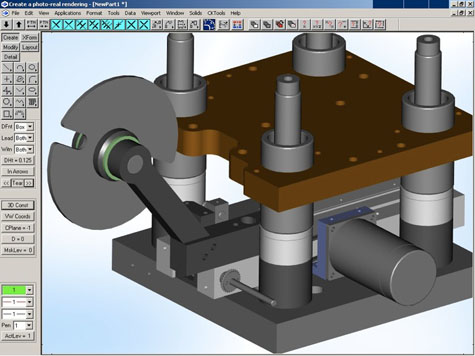

Rowley Spring and Stamping Corp. is staffed with many talented tool and die makers that have fabricated some of the most complex tooling to meet the specialty design configurations of each of our customers'. Today highly detailed part geometries and the use of more and more exotic materials have presented unique design challenges to our tool makers. With our team fabrication approach, each part is evaluated prior to the tooling design phase to ensure all aspects of the build will be according to Rowley Spring and Stampings strict design specifications. We have spent many years on developing our tool design standards that provide for longer tool life, ease of maintenance and reduction of material waste. Most aspects of the tooling fabrication take place in-house, allowing us to control work flow, timing, and adherence to tight tolerances.

Having a full staff of tool makers also allows us to provide the proper tool maintenance support for both our power press (progressive dies) and four slide departments. Each tool is placed on a regular maintenance schedule and the frequency of maintenance is determined by many factors such as materials being formed and punched, number of parts manufactured, and age of tool. Well maintained tools produce better quality parts. Contact the Rowley Spring and Stamping Corp. to get more information on our ability to design and build tooling to fabricate your parts.