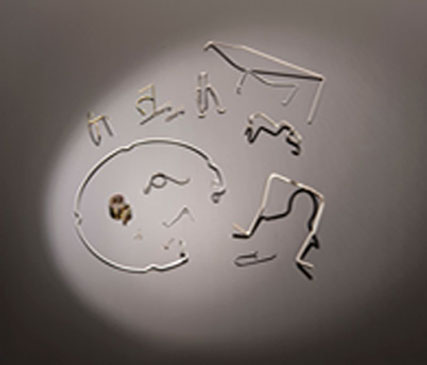

Wireforms

Custom wire forming is a very unique process and the wire forms can be designed for hundreds of thousands of configurations for many different applications. The purpose of a custom wire form varies greatly and can be found in almost anything that you come in contact with on a daily basis. You may be able to see them, or they may be deeply buried into a mechanism that affects our everyday lives. Technically, compression, extension and torsion springs are wire forms, but there are those situations where a non-traditional configuration is needed in order to meet certain needs or functions.

Whatever the shape or size, a wire form must be manufactured using one of a number of different methods. As a wire form manufacturer, Rowley Spring and Stamping Corp., has the capabilities to produce wire forms by either CNC wire forming machines or as a fourslide wireform (also referred to as a multi-slide and is the same type of machine that will produce fourslide stampings). This versatility allows us to objectively choose the most cost effective method to produce a wire form.